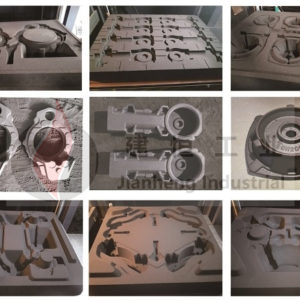

Auto horizontal flaksless

Main characteristics

1. The machine stable, low power consumption and long life time;

2. High level of auto, easy operating and lower labor cost;

3. Highly standardized, good parts interchangeable, fast and low-cost maintenance;

4. The sand could be compacted both inside and outside according to process requirement, which makes the mould better;

5. Mold release agent is sprayed automatically, which makes the demolding smoothly, casting surface glossily and no defect in the mould.

6. Electric cabinet and hydraulic station are all installation in the machine, which makes them compact and easy maintenance;

7. Low failure rate and the machine can diagnose the failure by itself.

Auto vertical flaskless line

No flasks, vertical parting, full automation, continuous and fast operatlon sand shooting pre-compactlon and hydraulic squeeze molding. Squeeze from two driections. Automatic mold size adjustment.

Man-machine interface enables adjustment and setting of technical parameters within specified ranges.

PLC, position sensors, pressure sensors and a liquid crystal display screen for fault monitoring, automatic alarming, remote control, and animation monitoring of dynamic inputs and outputs.

It is the most advanced and efficient green sand molding line at present. Its advantages are energy-saving, high productivity simple line formation, precise casting dimension and low investment. They are widely used for high quantity production of small and medium castings in various industries.

Tight-flask molding line

Air blowing pre-compaction plus multi-piston high pressure squeeze molding technology ensures high mold hardness, uniform mold compaction, low mismatch, precise casting and high yield.

The hydraulic multi-piston heads are used for squeezing with an adjustable pressure. The specific squeeze pressure is adjustable, with a maximum value of 1.5MPa.

This whole molding line combines electrical control, hydraulic and pneumatic transmission.

It is automatic, energy-efficient, and high casting precision. it has been widely used in quantity production of gray iron, ductil iron and cast steel high quality castings.

Aluminum melting and holding crucible furnace

If you need any information, please contact with us, we will provide you the most reasonable solutions.

Cast iron thermal analyser

| Technical parameter | ||

| Measurement item | Meassurement range | Measurement accuracy |

| Temp | 0-1370℃ | F.S±0.01% |

| CE% | 2.20-5.00% | ±0.05% |

| C% | 2.00%-4.80% | ±0.05% |

| Si% | 0.20%-4.50% | ±0.10% |

| SG% | 62%-95% | ±10.0% |

Function:

① Iron water grade, carbon equivalent, carbon content, silicon content, undercooling, spheroidization rate, tensile strength, etc.

② Automatic calculation of the amount of recarburizer, ferrosilicon and scrap.

③ Automatically plot carbon, silicon, carbon equivalent, primary crystal temperature, and eutectic temperature.

④ Calculate the supplementary amount according to the measurement result, the target component, the weight of molten iron, and the yield.

Casting ladle

If you need any information, please contact with us, we will provide you the most reasonable solutions.

Casting painting equipment

Our company can provide designing,manufacturing, and installing service of painting line for worldwide customers especially for foundry firms;

1.Ground conveying primer automatic assembly line

2.Self-propelled hoist finish painting automatic assembly line

3.New radiation casting spray paint room

4.Casting finishing grinding room and grinding dust collector

5.Casting paint drying room

6.New radiation paint drying room

7.New water dust removal mobile grinding room

8.Photo-oxygen catalysis and activated carbon adsorption equipment

Gravity casting machine

Mold size (length×width): 1000×1000 mm

Upper closing cylinder stroke: 700 mm

Lower closing cylinder stroke: 180 mm

Flip angle: 0~90°

Forming force (10Mpa): 196 KN

Oil pump motor power: 7.5 KW

High-frequency InfraredCarbon & Sulfur Analyzer

| Parameter | Measure scope | Analysis Precision | Time of analysis | Sensitivity | Sample weight | |

| Carbon | w(C) 0.0005%-6.0000% (can be extended to 99.999%) | RSD<1% | 25 to 60 seconds, could be adjusted. Around 35 seconds usually | C/s0.1ppm | 0.5g | |

| Sulfur | w(C) 0.0005%-0.5000% (can be extended to 99.999%) | RSD<1.5% | 0.5g |

Introduction:

CS995 Type High-frequency Infrared Carbon & Sulfur Analyzer compatible applying with WF-T88 Type High frequency automatic inductive combustion furnace,can fleetly and exactly measure the carbon and sulfur in steel, iron, alloy, nonferrous metals, cement, ore and other materials. This equipment is a high-tech products integrate light, motor, electronic, computer and analysis technology, with features of wide measuring scope, strong anti interference, multiple function, easy to operate, accurate and reliable analysis result.

Induction metal furnace

We supply the top quality induction furnace and competitive price to our customers. Furnace capacity range from 1T to 30T, and power supply rated power range from 250Kw to 18000Kw.

We also provideall the furnace supporting products, including water circulating system,hydraulic, dust collect equipment, lining push-out machanism, remote operatingpanel, safety guard protection and so on.