Description

| Specification | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | ZZ416A /ZZ416AC | ZZ416B/ ZZ416BC | ZZ416C / ZZ416D | ZZ417B | ZZ418A/ZZ418C | ZZ418B | ZZ419B | ZZA110A | ZZ411B |

| Size/ mm | 600*480*160/330 | 650*535*160/330 | 650*535*140/380 | 735*535*150/350 | 800*600*170/400 | 850*650*170/400 | 950*700*180/460 | 1000*800*200/600 | 1100*1050*200/270 |

| Productivity moulds/h | 280/350 | 280/350 | 400/500 | 480 | 280/350 | 300 | 280 | 260 | 200 |

| Without sand core, thickness of mould is 20mm. | |||||||||

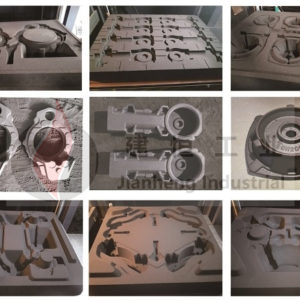

| Main components |

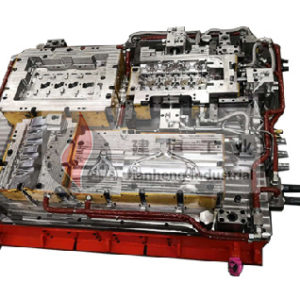

The veclical molding line is composed of molding machine sand feeder, parallel traveling core setter (optional), synchronous clamp (hold) conveyor, synchconous cooling conveyoc, shakeout, elecfcical control system, hydraulic and pneumatic systems.

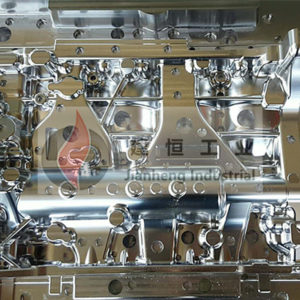

The vertical molding machine uses sand shooting and hydraulic squeeze molding; Stripping, molds close and transfer can be completed at the same time.

The optional core setter can be added to complete the line. Core setting rapidly and accurately with vacuum absorption mode.

The optional synchronous clamp (hold) conveyor transfers molds synchronous with molding machine for pouring and cooling

The optional synchronous cooling conveyor is after synchronous clamp (hold) conveyor to extend cooling time for different castings

The optional automatic pouring machine can be added to complete the line.

1.Auto vertical parting flaskless molding machine.Download.