Description

| Specifications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | YJZ8070 | YJZ10080 | YJZ12080 | YJZ12090 | YJZ13080 | YJZ13090 | YJZ145110 | YJZ150120 | YJZ195150 | YJZ220150 |

| Size/mm | 800*700*250/250 | 1000*800*350/300 | 1200*800*350/350 | 1200*900*250/300 1200*900*350/300 | 1300*800*300/300 1300*800*350/200 | 1300*900*350/3001300*900*350/350 | 1450*1100*400/400 | 1500*1200*450/450 | 1950*1500*550/450 | 2200*1500*350/300 |

| Productivity | 110 mould/ h | 110mould/ h | 90mould/ h | 90 mould/ h | 90 mould/ h | 90 mould/ h | 80 mould/ h | 70-80 mould/ h | 30-40 mould/ h | 30-40 mould/ h |

| sand (t/h) | 60-90 | 60-90 | 80-100 | 80-100 | 80-100 | 90-120 | 150 | 180 | 180 | 160 |

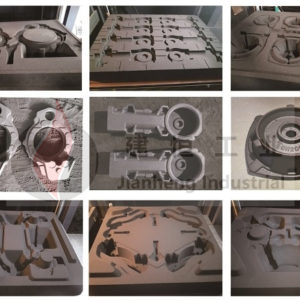

It can be divded into molding, core settrng, flasks closure, pourrng, cooling and shakeout sections.

It includes a horizontal multr-piston molding machine, whole set of auxiliary devices, mold conveyor, electrical contro system, hydraulic system, flasks and pattern plate bolsters.