No-bake coating

We provide high quality no-bake coating to our customers, and adjustment composition of coating to reduce cost according to the requirement from castings.

For more information, please refer to professional documents.

Sand coated iron mould production line

We provide professional sand coated iron mold casting technology services, including production lines, auxiliary materials.

1.Single molding machine, open production line or no line

2.Closed-loop production line consisting of simple machinery

3.Improved mechanized production line

Single molding machine, open production line or no line

Usually, the double-station molding machine or a single-stationmolding machine made by core-shooting machine can be used to complete modelingprocess, supporting the mould turning machine and the mould closing machine. Or,the crane is used to complete closing mould, pouring, and shaking out. It is used inthe following situations: the product quantity is small, trial-produced, or thecompany scale is particularly small.

Features:

1.Low investment and good productquality

2.Pouring on ground;

3.Low productivity;

4.High labor intensity;

5.Suitable for small batch production of largecasting

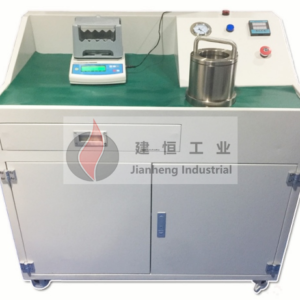

Vacuum aluminum liquid hydrogen analyzer

| Project | Unit | Parameter |

| Dimensions | mm | 1200X880X820 |

| Vacuum power | W | 370 |

| Pumping rate | L/S | 2 |

| Ultimate pressure | Pa | 0.97 |

| Working power | V | 220 |

| Oil consumption | L | 4 |

| Machine weight | KG | 70 |

Introduction: Designed according to the method of decompression and solidification test. The hydrogen in the liquid sample israpidly precipitated by vacuum pump. After the sample solidify, the hydrogen content of thealuminum liquid can be determined by comparing the surface quality of thesample with the standard sample. The actual mass proportion of the test blockis compared with the standard mass proportion to determine whether the aluminumliquid meets the requirements.

Furan resin

Furan resins are liquid thermosetting oligomers that undergo crosslinking reactions when heated and mixed with catalysts. They are primarily prepared by condensation polymerization of biobased furfuryl alcohol and its derivatives in the presence of strong acids.

To improve or modify their properties, they are often copolymerized with other monomers, such as formaldehyde (FF), phenol and furfural (2-furaldehyde). These resins are available in a wide range of viscosities that cure to highly crosslinked, fairly brittle polymers. They exhibit outstanding resistance to chemicals even at elevated temperatures, usually found only in much more expensive high performance engineering resins.

Furan resins are mainly used as chemical resistant cements and binders, for example for foundry products. Other applications include binders for explosives, wood adhesives, fiber composites, and other impregnating and coating compositions for demanding applications.

We supply high quality funan resin to our customers.

Modified sodium silicate

This product is the new generation of a new type of modified sodium silicate and modified sodium silicate curing agent for casting, which is jointly developed by our company and domestic universities and colleges.

Cupola

We can provide you the cupola solutions and help you to purchase the best cupola from China. This is a large-scale foundry furnace continuous melting, improve casting quality and reduce the cost of good casting furnace. In order to show our sincere cooperation thought and reduce the cost of customers, we would like to provide whole sets of cupola drawings. The customer can make and install the cupola by them self, we will only charge part of basic technique cost. If some parts can’t be made by the customer, we will help to produce it.

Spheroidizing station

1. Stabilize and improve the quality of ductile iron production;

2. Reduce production costs;

3. Elimination of environmental pollution from operations;

4. Mechanize or automate operations.

Resin sand equipment

We supply no-bake production line to our customers, and help our customers to design the layout and production.

Shot Blasting Machine

Features:

Compact design, easy operation, high sandblasting cleaning performance, low abrasive consumption,reliable cleaning and convenient dust removal.

This series of hook shot blasting machines are mainly used for surface cleaning and strengthening of steel structural parts, castings, aluminum alloy parts and other parts. It has the characteristics of no pits, double hooks without changing rails, compact structure and high productivity. Currently widely used in casting, forging, construction, steel, shipbuilding and other industries.