Auto vertical flaskless line

No flasks, vertical parting, full automation, continuous and fast operatlon sand shooting pre-compactlon and hydraulic squeeze molding. Squeeze from two driections. Automatic mold size adjustment.

Man-machine interface enables adjustment and setting of technical parameters within specified ranges.

PLC, position sensors, pressure sensors and a liquid crystal display screen for fault monitoring, automatic alarming, remote control, and animation monitoring of dynamic inputs and outputs.

It is the most advanced and efficient green sand molding line at present. Its advantages are energy-saving, high productivity simple line formation, precise casting dimension and low investment. They are widely used for high quantity production of small and medium castings in various industries.

Tight-flask molding line

Air blowing pre-compaction plus multi-piston high pressure squeeze molding technology ensures high mold hardness, uniform mold compaction, low mismatch, precise casting and high yield.

The hydraulic multi-piston heads are used for squeezing with an adjustable pressure. The specific squeeze pressure is adjustable, with a maximum value of 1.5MPa.

This whole molding line combines electrical control, hydraulic and pneumatic transmission.

It is automatic, energy-efficient, and high casting precision. it has been widely used in quantity production of gray iron, ductil iron and cast steel high quality castings.

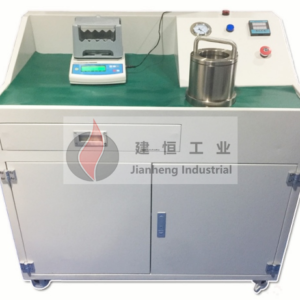

Cast iron thermal analyser

| Technical parameter | ||

| Measurement item | Meassurement range | Measurement accuracy |

| Temp | 0-1370℃ | F.S±0.01% |

| CE% | 2.20-5.00% | ±0.05% |

| C% | 2.00%-4.80% | ±0.05% |

| Si% | 0.20%-4.50% | ±0.10% |

| SG% | 62%-95% | ±10.0% |

Function:

① Iron water grade, carbon equivalent, carbon content, silicon content, undercooling, spheroidization rate, tensile strength, etc.

② Automatic calculation of the amount of recarburizer, ferrosilicon and scrap.

③ Automatically plot carbon, silicon, carbon equivalent, primary crystal temperature, and eutectic temperature.

④ Calculate the supplementary amount according to the measurement result, the target component, the weight of molten iron, and the yield.

Gravity casting machine

Mold size (length×width): 1000×1000 mm

Upper closing cylinder stroke: 700 mm

Lower closing cylinder stroke: 180 mm

Flip angle: 0~90°

Forming force (10Mpa): 196 KN

Oil pump motor power: 7.5 KW

High-frequency InfraredCarbon & Sulfur Analyzer

| Parameter | Measure scope | Analysis Precision | Time of analysis | Sensitivity | Sample weight | |

| Carbon | w(C) 0.0005%-6.0000% (can be extended to 99.999%) | RSD<1% | 25 to 60 seconds, could be adjusted. Around 35 seconds usually | C/s0.1ppm | 0.5g | |

| Sulfur | w(C) 0.0005%-0.5000% (can be extended to 99.999%) | RSD<1.5% | 0.5g |

Introduction:

CS995 Type High-frequency Infrared Carbon & Sulfur Analyzer compatible applying with WF-T88 Type High frequency automatic inductive combustion furnace,can fleetly and exactly measure the carbon and sulfur in steel, iron, alloy, nonferrous metals, cement, ore and other materials. This equipment is a high-tech products integrate light, motor, electronic, computer and analysis technology, with features of wide measuring scope, strong anti interference, multiple function, easy to operate, accurate and reliable analysis result.

No-bake coating

We provide high quality no-bake coating to our customers, and adjustment composition of coating to reduce cost according to the requirement from castings.

For more information, please refer to professional documents.

Sand coated iron mould production line

We provide professional sand coated iron mold casting technology services, including production lines, auxiliary materials.

1.Single molding machine, open production line or no line

2.Closed-loop production line consisting of simple machinery

3.Improved mechanized production line

Single molding machine, open production line or no line

Usually, the double-station molding machine or a single-stationmolding machine made by core-shooting machine can be used to complete modelingprocess, supporting the mould turning machine and the mould closing machine. Or,the crane is used to complete closing mould, pouring, and shaking out. It is used inthe following situations: the product quantity is small, trial-produced, or thecompany scale is particularly small.

Features:

1.Low investment and good productquality

2.Pouring on ground;

3.Low productivity;

4.High labor intensity;

5.Suitable for small batch production of largecasting

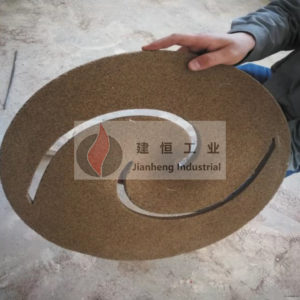

Vacuum aluminum liquid hydrogen analyzer

| Project | Unit | Parameter |

| Dimensions | mm | 1200X880X820 |

| Vacuum power | W | 370 |

| Pumping rate | L/S | 2 |

| Ultimate pressure | Pa | 0.97 |

| Working power | V | 220 |

| Oil consumption | L | 4 |

| Machine weight | KG | 70 |

Introduction: Designed according to the method of decompression and solidification test. The hydrogen in the liquid sample israpidly precipitated by vacuum pump. After the sample solidify, the hydrogen content of thealuminum liquid can be determined by comparing the surface quality of thesample with the standard sample. The actual mass proportion of the test blockis compared with the standard mass proportion to determine whether the aluminumliquid meets the requirements.

Furan resin

Furan resins are liquid thermosetting oligomers that undergo crosslinking reactions when heated and mixed with catalysts. They are primarily prepared by condensation polymerization of biobased furfuryl alcohol and its derivatives in the presence of strong acids.

To improve or modify their properties, they are often copolymerized with other monomers, such as formaldehyde (FF), phenol and furfural (2-furaldehyde). These resins are available in a wide range of viscosities that cure to highly crosslinked, fairly brittle polymers. They exhibit outstanding resistance to chemicals even at elevated temperatures, usually found only in much more expensive high performance engineering resins.

Furan resins are mainly used as chemical resistant cements and binders, for example for foundry products. Other applications include binders for explosives, wood adhesives, fiber composites, and other impregnating and coating compositions for demanding applications.

We supply high quality funan resin to our customers.

Modified sodium silicate

This product is the new generation of a new type of modified sodium silicate and modified sodium silicate curing agent for casting, which is jointly developed by our company and domestic universities and colleges.