Alloy rod

We supply alloy rod and help our customers to design the layout of alloy rod.

Founry material on lost foam process

We supply these material to our customers on lost foam process

- EPS beads;

- Glue

- repair cream

- ……

Cold box resin

We help our customers using our cold box resin, provide production guide until production stable.

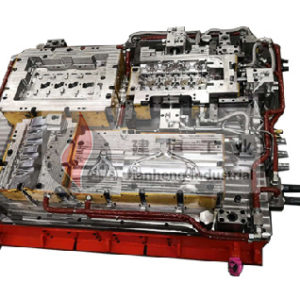

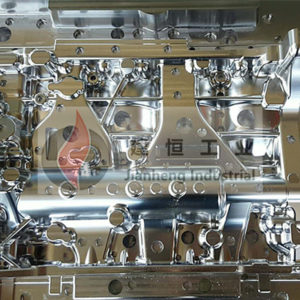

Cold box mold

We help our customers to design and make cold box mold; and help our customers to trial production in china if need. our mold factory have 160 workers, and more than 30years experience on mold design and production.

Cold box equipment

Features

1.High productivity;

2.High yield;

3.High investment cost;

4.Suitable for big batch and complex castings.

Coated sand

Coated sand is a kind of high-quality selected natural sand as the sand base, resin coating system with special performance and the most ideal process technology. According to the technical requirements of different users, it strives to perform at room temperature, high temperature performance, collapsibility, and flowability. The most perfect combination of performance, casting surface roughness, etc., is widely used in automobile engines, diesel engines, hydraulic parts and other industries.

Core/Shell shooting machine

We can provide suitable choice for your core making system to manufacture high-quality sand cores with precise size and smooth purface. We have kinds of core shooting machines: hotbox or coldbox,single station or multi-station,horizontal parting or vertical parting.

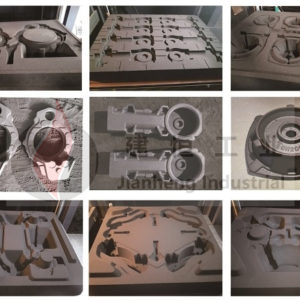

Wooden pattern

We supply wooden pattern to our customers.

- Resin sand pattern

- V-process pattern

Green sand molding machine

Green sand moulding machine

We provide green sand molding machine to customers, they can form loop lines and stand-alone equipment. the capability of these machine from 40 to 240moulds per h;

We provide all size moulding machine according the requirement from customers. and help our customers to using it and until products is stable.

Flaskless moulding machine

The flaskless moulding machine have lower invest cost, and operating easy. suit for some small foundry and new products develop.

The biggest size of workbench is 600*700mm, suit for most of green sand products.

Flask moulding machine

The flask moulding machine suit for some higher requirement castings. equipment design to auto and half-auto type according to customers requirement. these machine match bigger flask to suit for some bigger castings.

Auto horizontal flaksless

Main characteristics

1. The machine stable, low power consumption and long life time;

2. High level of auto, easy operating and lower labor cost;

3. Highly standardized, good parts interchangeable, fast and low-cost maintenance;

4. The sand could be compacted both inside and outside according to process requirement, which makes the mould better;

5. Mold release agent is sprayed automatically, which makes the demolding smoothly, casting surface glossily and no defect in the mould.

6. Electric cabinet and hydraulic station are all installation in the machine, which makes them compact and easy maintenance;

7. Low failure rate and the machine can diagnose the failure by itself.