Cold box equipment

Features

1.High productivity;

2.High yield;

3.High investment cost;

4.Suitable for big batch and complex castings.

Core/Shell shooting machine

We can provide suitable choice for your core making system to manufacture high-quality sand cores with precise size and smooth purface. We have kinds of core shooting machines: hotbox or coldbox,single station or multi-station,horizontal parting or vertical parting.

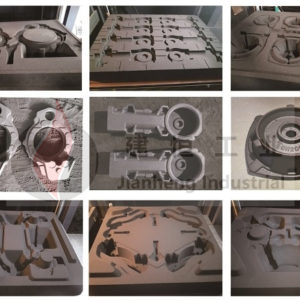

Wooden pattern

We supply wooden pattern to our customers.

- Resin sand pattern

- V-process pattern

Green sand molding machine

Green sand moulding machine

We provide green sand molding machine to customers, they can form loop lines and stand-alone equipment. the capability of these machine from 40 to 240moulds per h;

We provide all size moulding machine according the requirement from customers. and help our customers to using it and until products is stable.

Flaskless moulding machine

The flaskless moulding machine have lower invest cost, and operating easy. suit for some small foundry and new products develop.

The biggest size of workbench is 600*700mm, suit for most of green sand products.

Flask moulding machine

The flask moulding machine suit for some higher requirement castings. equipment design to auto and half-auto type according to customers requirement. these machine match bigger flask to suit for some bigger castings.

Auto horizontal flaksless

Main characteristics

1. The machine stable, low power consumption and long life time;

2. High level of auto, easy operating and lower labor cost;

3. Highly standardized, good parts interchangeable, fast and low-cost maintenance;

4. The sand could be compacted both inside and outside according to process requirement, which makes the mould better;

5. Mold release agent is sprayed automatically, which makes the demolding smoothly, casting surface glossily and no defect in the mould.

6. Electric cabinet and hydraulic station are all installation in the machine, which makes them compact and easy maintenance;

7. Low failure rate and the machine can diagnose the failure by itself.

Auto vertical flaskless line

No flasks, vertical parting, full automation, continuous and fast operatlon sand shooting pre-compactlon and hydraulic squeeze molding. Squeeze from two driections. Automatic mold size adjustment.

Man-machine interface enables adjustment and setting of technical parameters within specified ranges.

PLC, position sensors, pressure sensors and a liquid crystal display screen for fault monitoring, automatic alarming, remote control, and animation monitoring of dynamic inputs and outputs.

It is the most advanced and efficient green sand molding line at present. Its advantages are energy-saving, high productivity simple line formation, precise casting dimension and low investment. They are widely used for high quantity production of small and medium castings in various industries.

Tight-flask molding line

Air blowing pre-compaction plus multi-piston high pressure squeeze molding technology ensures high mold hardness, uniform mold compaction, low mismatch, precise casting and high yield.

The hydraulic multi-piston heads are used for squeezing with an adjustable pressure. The specific squeeze pressure is adjustable, with a maximum value of 1.5MPa.

This whole molding line combines electrical control, hydraulic and pneumatic transmission.

It is automatic, energy-efficient, and high casting precision. it has been widely used in quantity production of gray iron, ductil iron and cast steel high quality castings.

Gravity casting machine

Mold size (length×width): 1000×1000 mm

Upper closing cylinder stroke: 700 mm

Lower closing cylinder stroke: 180 mm

Flip angle: 0~90°

Forming force (10Mpa): 196 KN

Oil pump motor power: 7.5 KW

Sand coated iron mould production line

We provide professional sand coated iron mold casting technology services, including production lines, auxiliary materials.

1.Single molding machine, open production line or no line

2.Closed-loop production line consisting of simple machinery

3.Improved mechanized production line

Single molding machine, open production line or no line

Usually, the double-station molding machine or a single-stationmolding machine made by core-shooting machine can be used to complete modelingprocess, supporting the mould turning machine and the mould closing machine. Or,the crane is used to complete closing mould, pouring, and shaking out. It is used inthe following situations: the product quantity is small, trial-produced, or thecompany scale is particularly small.

Features:

1.Low investment and good productquality

2.Pouring on ground;

3.Low productivity;

4.High labor intensity;

5.Suitable for small batch production of largecasting

Resin sand equipment

We supply no-bake production line to our customers, and help our customers to design the layout and production.