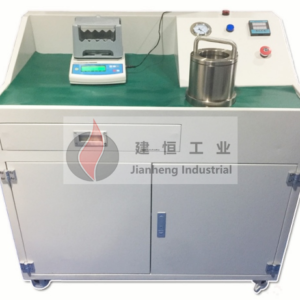

Cast iron thermal analyser

| Technical parameter | ||

| Measurement item | Meassurement range | Measurement accuracy |

| Temp | 0-1370℃ | F.S±0.01% |

| CE% | 2.20-5.00% | ±0.05% |

| C% | 2.00%-4.80% | ±0.05% |

| Si% | 0.20%-4.50% | ±0.10% |

| SG% | 62%-95% | ±10.0% |

Function:

① Iron water grade, carbon equivalent, carbon content, silicon content, undercooling, spheroidization rate, tensile strength, etc.

② Automatic calculation of the amount of recarburizer, ferrosilicon and scrap.

③ Automatically plot carbon, silicon, carbon equivalent, primary crystal temperature, and eutectic temperature.

④ Calculate the supplementary amount according to the measurement result, the target component, the weight of molten iron, and the yield.

High-frequency InfraredCarbon & Sulfur Analyzer

| Parameter | Measure scope | Analysis Precision | Time of analysis | Sensitivity | Sample weight | |

| Carbon | w(C) 0.0005%-6.0000% (can be extended to 99.999%) | RSD<1% | 25 to 60 seconds, could be adjusted. Around 35 seconds usually | C/s0.1ppm | 0.5g | |

| Sulfur | w(C) 0.0005%-0.5000% (can be extended to 99.999%) | RSD<1.5% | 0.5g |

Introduction:

CS995 Type High-frequency Infrared Carbon & Sulfur Analyzer compatible applying with WF-T88 Type High frequency automatic inductive combustion furnace,can fleetly and exactly measure the carbon and sulfur in steel, iron, alloy, nonferrous metals, cement, ore and other materials. This equipment is a high-tech products integrate light, motor, electronic, computer and analysis technology, with features of wide measuring scope, strong anti interference, multiple function, easy to operate, accurate and reliable analysis result.

Vacuum aluminum liquid hydrogen analyzer

| Project | Unit | Parameter |

| Dimensions | mm | 1200X880X820 |

| Vacuum power | W | 370 |

| Pumping rate | L/S | 2 |

| Ultimate pressure | Pa | 0.97 |

| Working power | V | 220 |

| Oil consumption | L | 4 |

| Machine weight | KG | 70 |

Introduction: Designed according to the method of decompression and solidification test. The hydrogen in the liquid sample israpidly precipitated by vacuum pump. After the sample solidify, the hydrogen content of thealuminum liquid can be determined by comparing the surface quality of thesample with the standard sample. The actual mass proportion of the test blockis compared with the standard mass proportion to determine whether the aluminumliquid meets the requirements.